An Air Cooled Condenser is a critical component of the animal waste rendering process, designed to remove heat from the rendering vapor and condense it into a liquid form for further processing or disposal.

The Air Cooled Condenser operates by passing hot rendering vapor through a series of finned tubes or coils, where it comes into contact with ambient air. As the vapor cools, it releases heat energy, which is transferred to the surrounding air, causing the vapor to condense into a liquid state.

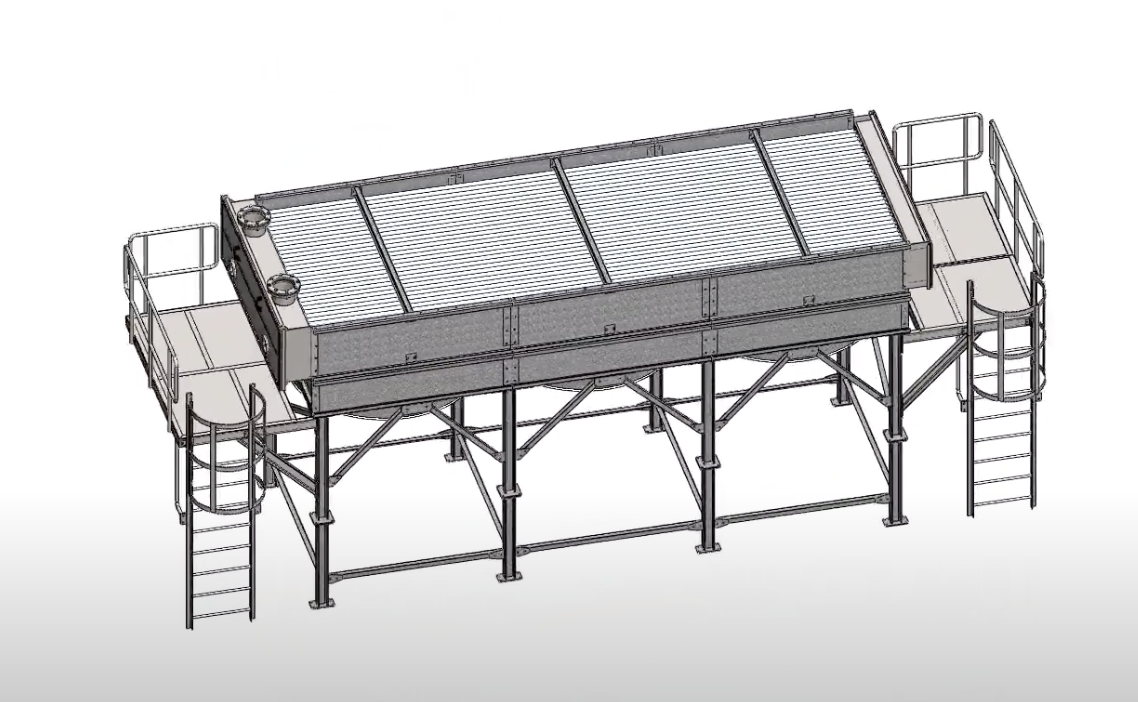

Key features of an Air Cooled Condenser typically include a robust construction capable of withstanding high temperatures and pressures, efficient heat transfer surfaces for maximum cooling efficiency, and adjustable airflow mechanisms to optimize performance under varying operating conditions.

In the animal rendering industry, the Air Cooled Condenser plays a crucial role in the production of high-quality rendered products, providing effective heat removal and condensation of rendering vapor, ensuring product quality, and promoting environmental sustainability by reducing energy consumption and greenhouse gas emissions.

Efficient Heat Removal: Our Air Cooled Condenser effectively removes heat from rendering vapor, ensuring rapid condensation and maximum cooling efficiency for optimal performance.

Robust Construction: Built to withstand the rigors of continuous use, our Air Cooled Condenser features a rugged construction and high-quality materials, ensuring reliable performance and longevity even in demanding environments.

Adaptable to Varied Environments: Our Air Cooled Condenser is engineered to perform reliably in diverse operating conditions, including fluctuating ambient temperatures and humidity levels, ensuring consistent performance year-round.

Seamless Integration: Compatible with a wide range of rendering equipment and systems, our Air Cooled Condenser seamlessly integrates into existing workflows, enhancing overall efficiency and productivity.