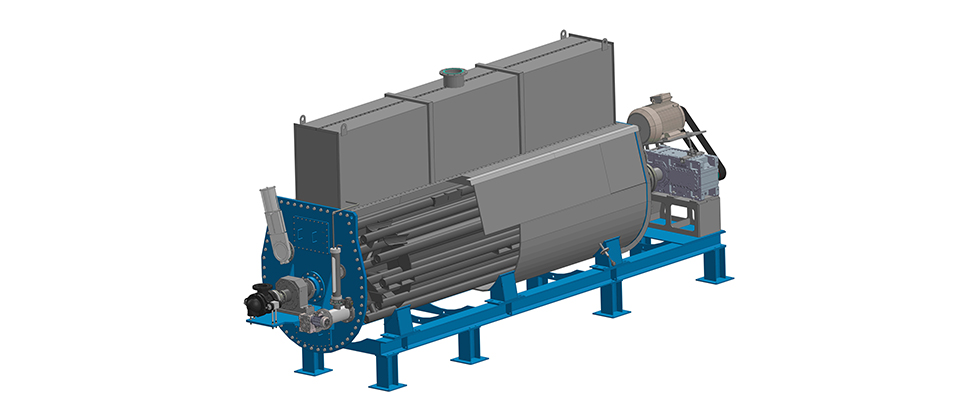

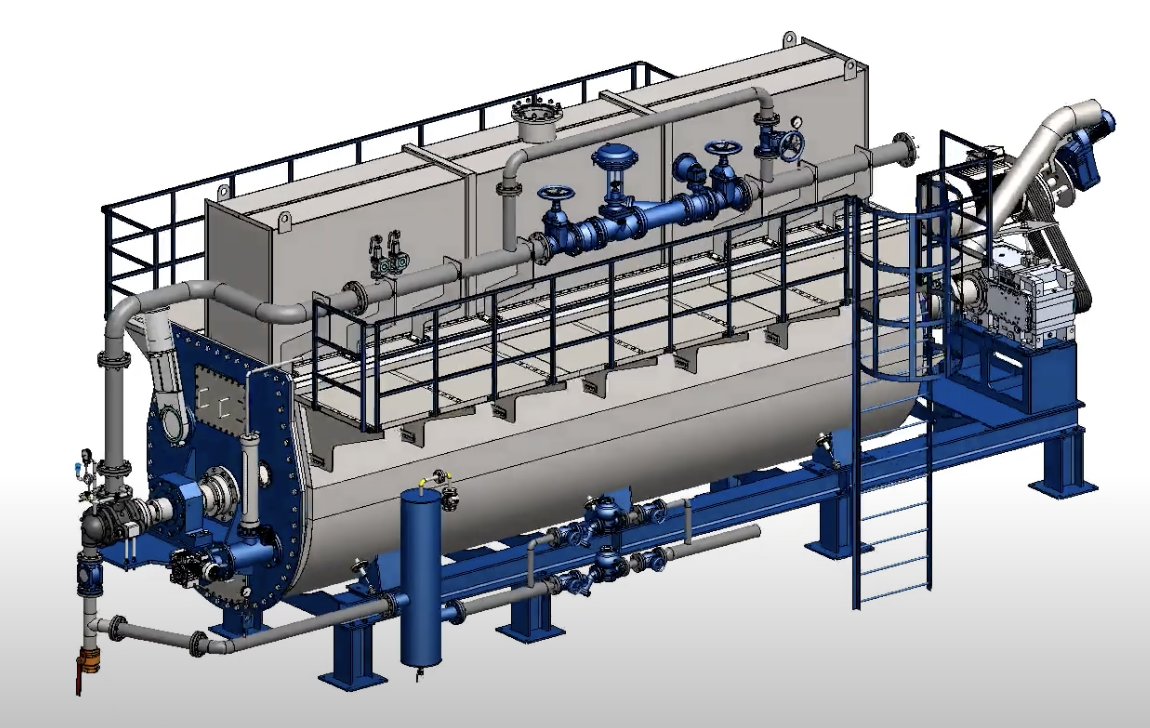

A Continuous Cooker is an integral component of the animal waste rendering process, designed to efficiently convert raw animal by-products into valuable rendered products in a continuous, uninterrupted operation.

Unlike batch cookers, which process materials in discrete batches, a Continuous Cooker operates continuously, feeding raw materials into the system at one end while extracting rendered products at the other. This continuous flow allows for a steady and efficient rendering process, maximizing throughput and minimizing downtime.

The Continuous Cooker utilizes a combination of high temperatures, pressure, and agitation to break down organic matter, sterilize the material, and extract fats, proteins, and other nutrients from the animal waste. This process results in the production of stable, safe, and high-quality rendered products suitable for various applications, including animal feed, biodiesel, and industrial fats.

Key features of a Continuous Cooker typically include robust construction capable of withstanding high temperatures and pressure, advanced heating and mixing systems to ensure thorough cooking and sterilization, and precise control mechanisms to maintain optimal processing conditions.

In the animal rendering industry, the Continuous Cooker offers significant advantages in terms of efficiency, productivity, and scalability, making it an essential asset for rendering facilities seeking to maximize their output and profitability.

Continuous Operation: Our Continuous Cooker enables uninterrupted processing of raw animal by-products, ensuring a constant flow of material through the system and maximizing overall throughput.

High Efficiency: With its continuous operation design, our Continuous Cooker offers exceptional efficiency, minimizing downtime and maximizing productivity for rendering operations of all scales.

Optimized Heating and Mixing: Equipped with advanced heating and mixing systems, our Continuous Cooker ensures thorough cooking and sterilization of the material, resulting in high-quality rendered products with optimal nutritional value.

Precise Control: Featuring precise temperature and pressure control mechanisms, our Continuous Cooker allows operators to maintain optimal processing conditions, ensuring consistent product quality and safety.

Cost-Effective Operation: Investing in our Continuous Cooker helps rendering facilities optimize their production processes, minimize operating costs, and maximize profitability by maximizing throughput and efficiency.